A Range of Solutions to Improve Efficiency

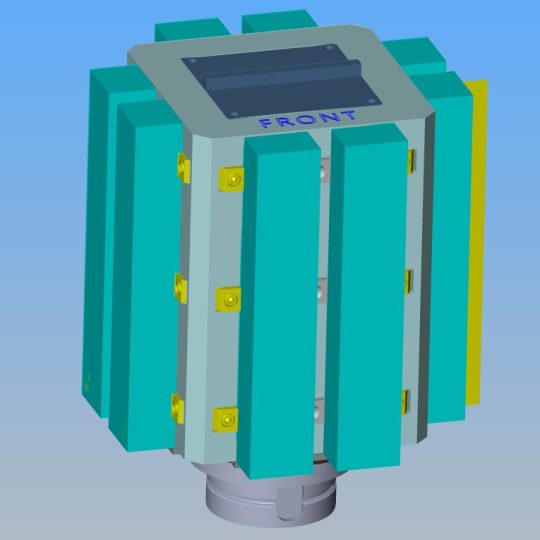

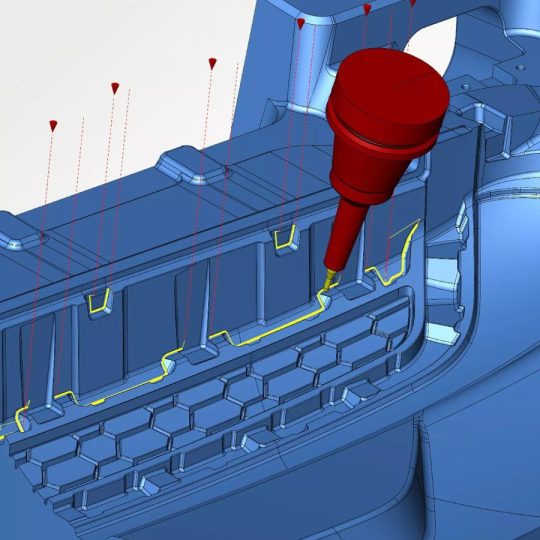

CAD/CAM Consultant

Automation

Staff Training

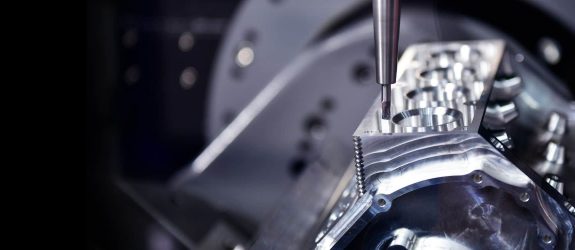

Machine Investments

Premises Relocation